Our Technology

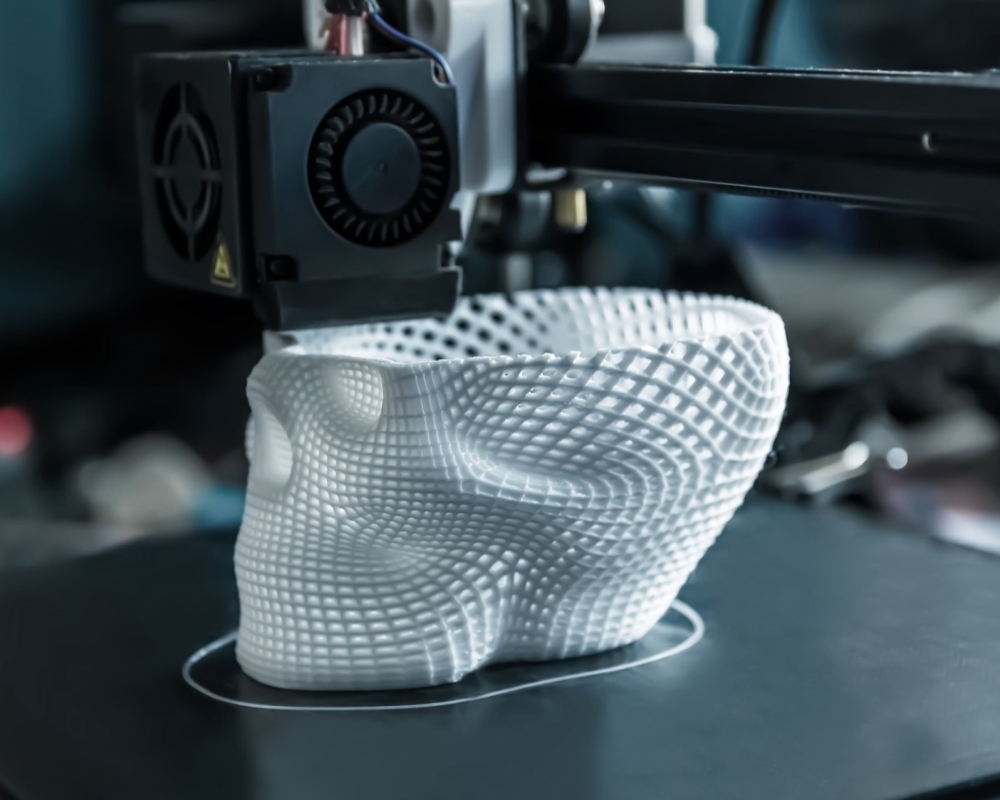

Nano-Imprinting technology is a manufacturing process technology that directly forms fine patterns in nanometer (nm) units on various materials and has developed its own technology to overcome the limitations and problems occurring in the existing photolithography process.

The core point of this technology is to manufacture a mold with fine patterns of various shapes on a substrate called a ‘mold’. The point is to easily duplicate the pattern by printing it directly on the material surface using this mold. This enables the implementation of ultra-fine patterns and mass production in various fields.

Key Features

Combining lenticular technology and microlens technology, 3D stereoscopic technology is an innovative solution that maximizes visual depth and detail by utilizing the advantages of each technology.

By combining the three-dimensional movement of lenticular technology with the ultra-precise image implementation of microlens technology, immersive visual content and high-quality products can be produced. The technology provides a differentiated three-dimensional experience in various industries, and embodies functional elements and aesthetic values at the same time.

Key Features

Combining lenticular technology and nanoimprinting technology, 3D stereoscopic technology is a cutting-edge visual technology that simultaneously embodies three-dimensional depth, movement effect, and ultra-precise detail.

By fusing the unique three-dimensional expression of lenticular lenses with nanoimprinting’s ability to form ultra-fine structures, it provides an immersive and differentiated visual experience.

This technology is used in a variety of industries and opens up innovative possibilities beyond traditional 3D technologies.

Key Features

- Insertion of non-replicable security patterns on the surface of lenticular lenses with nanoimprinting technology.

- It can be used as a solution for authenticating and preventing counterfeiting such as identification, passport, and currency.

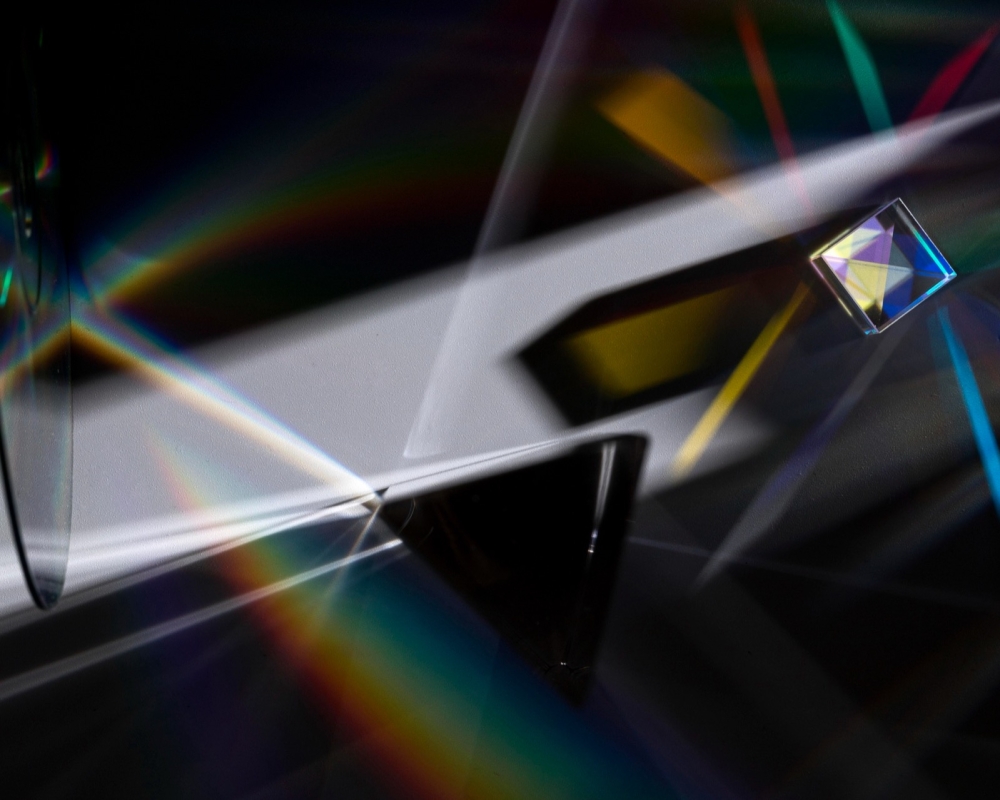

Color conversion technology using lenticular lenses is a technology that utilizes the unique optical properties of lenticular lenses to realize the effect of changing colors depending on the angle of observation. This technology provides visual dynamism and is used in various industries such as high-end consumer goods, advertising, security, and art.

The color looks different depending on the angle the observer sees, adding a unique charm to the product or content.

Key Features

Stereoscopic products using lenticular and microlenses provide unique visual effects and sophisticated patterns, but the rough texture of the lens surface can negatively affect the product’s sense of use or appearance.

To address this, the technology of smoothing the surface is one that focuses on enhancing the luxuriousness and the softness of the touch while maintaining the functional properties of the lens.

Key Features

Partial stereoscopic pattern application technology is a cutting-edge manufacturing technology that provides a unique and functional design by selectively implementing stereoscopic patterns only on specific areas of the product’s surface.

The combination of specific part stereoscopic and nanoimprinting patterns creates luxurious images of products. This technology maximizes visual effects and plays an important role in enhancing the aesthetic value and usability of products.

Key Features

- A three-dimensional pattern can only be formed in a specific part of the product surface, not the entire surface.

- Different textures and designs are combined to provide a variety of visual effects.

Microlens anti-counterfeiting technology is a technology that effectively prevents forgery and falsification by implementing ultra-precise images through the lens. It can simply authenticate with the naked eye and is used in various fields such as identification, passport, currency, and product authentication.

It is attracting attention as a next-generation security solution because it can be combined with digital authentication such as holograms and QR codes. It has low manufacturing cost, mass production is possible, and it is becoming a sustainable technology through eco-friendly processes.

In particular, it is expected to be adopted in a wider range of industries due to digitalization and increased demand for global security

Key Features

- Insertion and magnification of microimages that cannot be seen with the naked eye. .

- The lens array identifies hidden images or patterns.

- Fused with additional security elements such as holograms and fluorescent inks.

- Enhanced security through complex anti-counterfeiting systems.

- Economic technology applicable to mass production processes.

- Secure elements of various sizes and formats can be implemented.